Breadcrumb

- California Offshore Winds

- Offshore Wind Infrastructure

Offshore Wind Infrastructure

- Why offshore wind? What is floating offshore wind? Why is floating offshore wind being developed in California?

Both fixed and floating offshore wind take advantage of strong ocean winds that are available in the afternoon and evening when other renewable sources including onshore wind have less reliability.. The first offshore wind projects were fixed projects located in relatively shallow water (60 meters) with a monopile that attaches the wind turbine to the seabed floor.

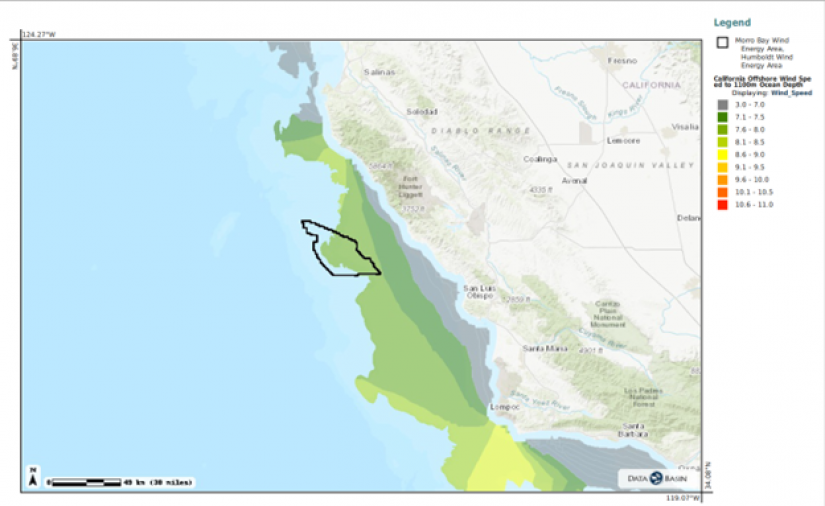

To access higher and more consistent winds located farther offshore, floating offshore wind technology was developed for deeper water depths (more than 60 meters) where it would be impossible to use monopile technology. Globally 80% of offshore wind resources are in waters greater than 60 meters; 58% of U.S. offshore wind is in deep waters. The federal lease areas in California have deep water making floating offshore wind the preferred choice. Wind speeds are consistently high in the deep water where the Morro Bay and Humboldt Wind Energy Areas are located.

- What is the marine-based infrastructure supporting floating offshore wind development?

Floating offshore wind is produced by wind farms that contain numerous wind turbines connected to a floating structure. The structure is secured by moorings and anchors to the seabed floor.

A wind turbine consists of several components including a hub, blades, nacelle, and tower. Large wind turbines will be more economical over the lifetime of a project. Some of the existing major turbine manufacturers include Siemens, Vestas Wind , and General Electric. A hub supports the turbine’s blades and optimizes blade angles. Blades create mechanical energy. The nacelle takes the mechanical energy and converts it to electrical energy. Individual wind turbines will be spaced across lease areas over 1 mile apart.

Example of a turbine

There are multiple different designs for the floating platforms. These platforms are typically made from concrete and steel. Developers will choose between spar platforms which are stabilized by a single post consisting of weights and a buoyancy tank that stands deep within the water column, semisubmersible platforms that look like a triangle and distribute buoyancy closer to the water surface, and tension-leg platforms that have submerged buoyancy tanks and tension through the mooring lines. The major difference between a floating wind platform and an oil platform is that the load on a floating wind platform is dynamic rather than static.

Mooring lines are large in diameter and are made from chain or synthetic ropes. They may be connected tightly to the anchoring point on the sea bed floor (taut mooring) or just tensioned to the load of their own weight (catenary mooring).

Types of Floating Platforms

Different types of anchors exist to connect moorings to the seabed floor. Dragging anchors are similar to anchors used by ships. Suction anchors (also called suction piles and suction caissons depending on whether they are installed in a vertical or horizontal aspect) are structures that rest on a sandy or sandy-loamy seabed floor and create a pressure difference for anchoring. Other types of anchors including drilled piles and gravity anchors exist but are not favored by the industry unless other options are not feasible. Drilled piles require a special boat for installation and pile-driving generates noise. Gravity anchors are large concrete structures with sizable seabed footprints.

Example of a Drag Anchor

Example of a Suction Anchor

Every turbine will be connected to cables that will take electricity to an offshore substation that collects power and prepares it for transmission through an export cable to the onshore grid.

- How big are the wind turbines?

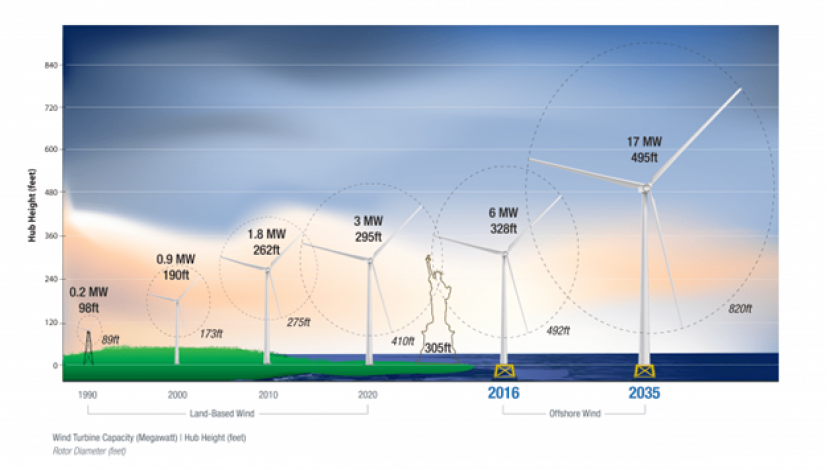

Offshore wind turbines will be much larger than onshore wind turbines.

- Are there examples of existing and proposed floating offshore wind projects outside of the US?

There are existing offshore floating wind projects in Portugal, Scotland, and Norway. In Portugal, Windfloat Atlantic is a pilot project of 2MW operating in depths of 100 meters about 20 kilometers (12.5 miles) offshore. In Scotland, Hywind Scotland is a pilot project 25 km (16 miles) offshore with 5 turbines operating in water depths between 95-120 meters with installed capacity for 30 MW. In Norway, Hywind Tampen is a floating offshore project located 140 km (87 miles) offshore in water between 260 and 300 meters deep. The project has a production capacity of 88 MW. Numerous new floating offshore wind projects have been proposed including the Arven project in the United Kingdom (2.3 GW), Kultje project in Sweden (2.15 GW), Linosa project in Italy (1 GW), Bellrock Project in United Kingdom (1.2 GW), Ayre Project (1 GW), Broadshore Project in United Kingdom (900 MW), and Nao Victoria project in Spain (990 MW). Korea also has a 1.2 GW proposed project in more than 200 meters depths over 80 km (49.7 miles) from shore and a 1.5 GW project in 150-meter deep water about 60 km offshore (37 miles). Other countries such as Japan, Brazil, and Australia are also pursuing floating projects.

- Where will California’s offshore floating wind technology be manufactured and assembled?

Developers have not yet made decisions about what manufacturing companies will receive contracts for wind infrastructure components; it is not useful to speculate about manufacturing sites. The wind developers do have credits in their lease contract for workforce development which may be used for training of the U.S. supply chain workforce. Assembly of these components requires large port areas. There are ongoing discussions of developing the Port of Humboldt as a wind assembly area. The Port of Long Beach is identifying financing to develop a potentially 400-acre wind assembly terminal called Pier Wind. Major Components for the Morro Bay Wind Energy Area are likely to be assembled in Long Beach and towed to the site for installation. For example of the towing, please see the towout of Windfloat Atlantic from the port of Ferrol in Galicia, Spain to Viano del Castelo in the north of Portugal. https://www.youtube.com/watch?v=xjHRGuQwBV0