Photo: Cultured ulva (Monterey Bay Seaweeds)

PROJECT HIGHLIGHT

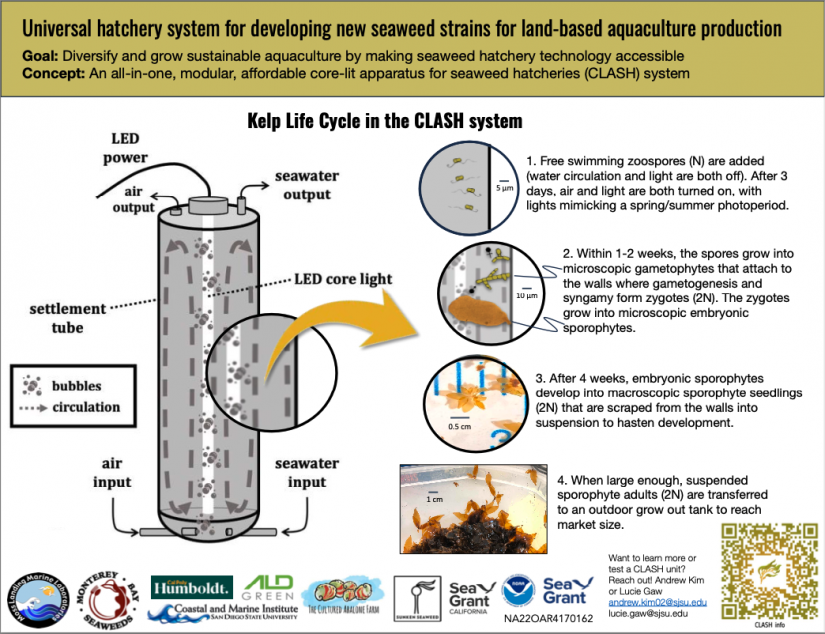

Researchers are developing innovative, non-proprietary hatchery technology to help launch a robust domestic seaweed industry and reduce America's $33 million seaweed import deficit.

PROJECT SUMMARY

The vast majority of seaweed consumed in the United States is imported from Asia, creating an import-export deficit of more than $33 million annually. While seaweed represents a product ripe for highly sustainable land-based farming, the missing piece has been adequate hatchery facilities needed to supply domestic seaweed producers with the seeds they need to grow crops.

A funding grant from the National Oceanic and Atmospheric Administration and National Sea Grant Office is addressing this challenge by supporting the development of novel, non-proprietary hatchery technology for land-based seaweed production. Project partner Dr. Michael Graham, professor at Moss Landing Marine Laboratories, and his colleagues have created a prototype modular hatchery system called CLASH (Core-Lit Apparatus for Seaweed Hatcheries) to address the seaweed seed shortage. California Sea Grant Extension Specialist Theresa Talley and a team of aquaculture scientists and industry members are working to refine the system design, develop accompanying protocols, test the system in industry settings throughout the state and get the technology into the hands of new growers.

The research team has made significant progress in developing and testing the CLASH systems, with seven active units currently being tested and refined by researchers at three partnering institutions: CalPoly Humboldt, Moss Landing Marine Lab and San Diego State University. The team has successfully cultured multiple kelp species including bull kelp, giant kelp and winged kelp, completed full life-cycles in the CLASH units and developed comprehensive Standard Operating Procedures for building and operating the systems. Through scientific conferences and educational outreach events like the California Seaweed Festival, the researchers are actively sharing their findings with potential end-users to support the growth of domestic seaweed aquaculture.

Photo: CLASH system setup (P. Tahimic, Cal Poly Humboldt)

Photo: Materials for building multiple CLASH system main tubes (A. Palinkas, at Moss Landing Marine Laboratories)

Photo: CLASH system core-light rods wrapped in LED light strips and dipped in epoxy are being wheeled into direct sunlight for curing (A. Palinkas, at Moss Landing Marine Laboratories)

Associated project team

- Theresa Talley, Lead PI, California Sea Grant

- Michael Graham, co-PI, Moss Landing Marine Laboratories

- Scott Hamilton, co-PI, Moss Landing Marine Laboratories

- Rafael Cuevas-Uribe, co-PI, Cal Poly Humboldt

- Matt Edwards, co-PI, San Diego State University

- Ashleigh Palinkas, Staff Research Associate, California Sea Grant

- Dan Gossard, Professional, Moss Landing Marine Laboratories

- Andrew Kim, Professional, Moss Landing Marine Laboratories

- Jessica Franks, Graduate Student Research Assistant, San Jose State University

- Lucie Gaw, Graduate Student Research Assistant, San Jose State University

- Jacob Ogawa, Graduate Student Research Assistant, San Diego State University

Phillip Tahimic, Graduate Student Research Assistant, Cal Poly Humboldt

Photo: CLASH Version 1.0 display and demonstration at the California Seaweed Festival in San Diego, CA November 2023 (T. Talley, California Sea Grant)

related news

Theresa Sinicrope Talley

Theresa Sinicrope Talley